According to Tennessee House Bill 1084, signed into law in 2013, in order to be called “Tennessee whiskey,” a distilled spirit must a) be made in Tennessee b) follow composition standards that mirror bourbon and c) be filtered through sugar maple charcoal in a system known as The Lincoln County Process. Jack Daniel’s, in addition to being the most well-known Tennessee whiskey, is the distillery responsible for making charcoal filtration a Tennessee industry standard. Below, in order to get the full measure of the large selection of rare and collectible bottles of Jack Daniel’s in our Fine Wine & Rare Spirits Auction (thirty five lots in total), we get to the bottom of charcoal filtration and its history in American distilling.

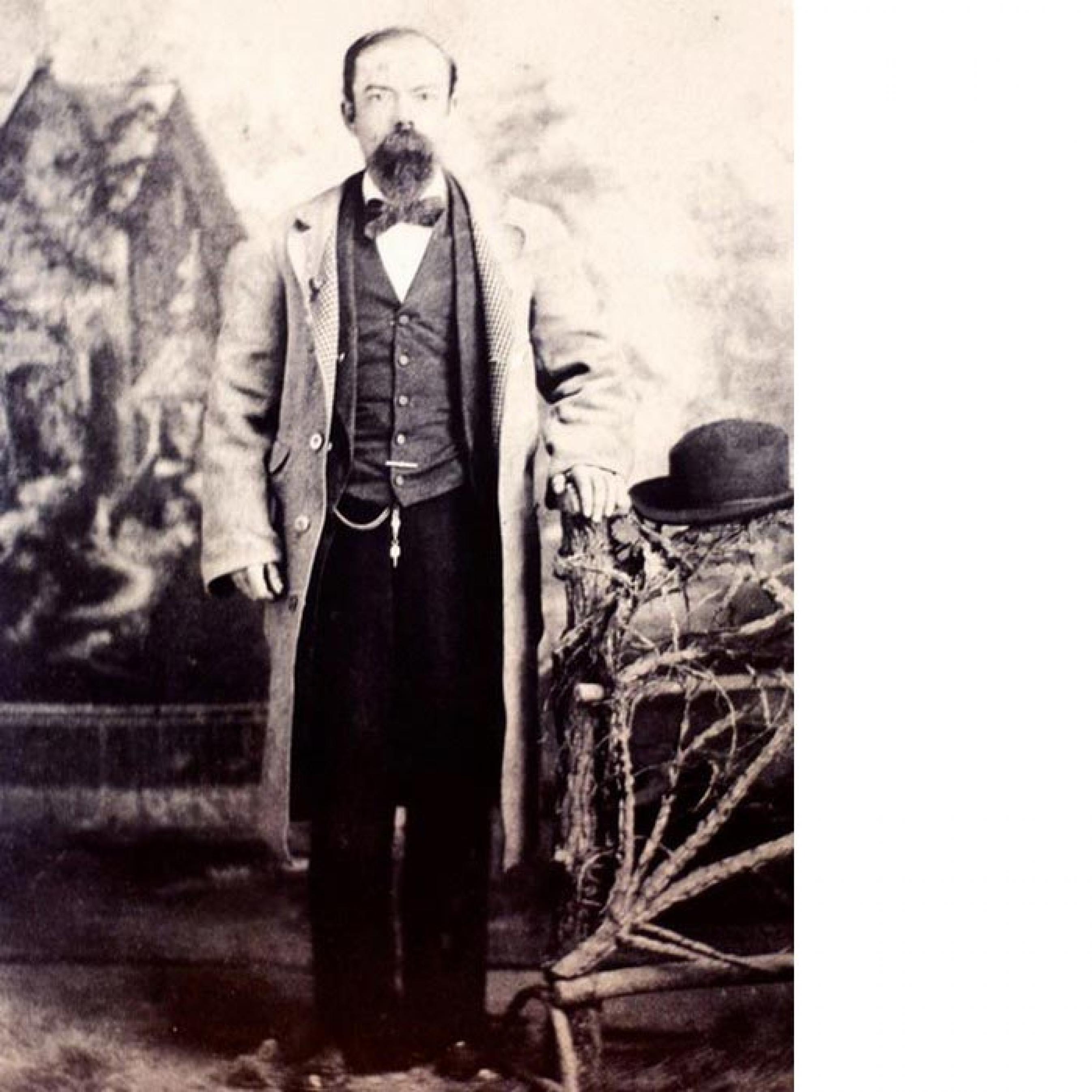

Jack Daniel

Centuries of Charcoal

In the modern world, activated charcoal filters are used in everything from cigarettes to cars to homemade coronavirus face masks. But the ubiquitous adoption of charcoal filtration took millennia. The earliest evidence of charcoal being used for purification comes from an Egyptian papyrus dating to 1500 BC. In that instance, the Egyptians applied charcoal to festering wounds to make them less odiferous. Somewhere in the next thousand or so years, people figured out that charcoal was effective on unwanted flavors as well as odors - by around 400 AD, the Phoenicians were using charred barrels to store their water on long sea journeys to improve its taste (creating, essentially, the first ever Brita filter). The system of actually passing a substance through a layer of charcoal to draw out impurities took hold as a large scale industrial practice when the Europeans developed a taste for refined sugar in the 19th century, and they discovered that they could use charcoal to draw unwanted flavor and color components out of beet and cane sugar. But in the intervening years, people all over the world used charcoal as a home method of purification. And it’s likely in that scrappy way that charcoal filtration made its way into the distillation process.

Charcoal Meets Whiskey

Who first applied charcoal filtration to whiskey-making in the United States is a matter of some debate. The Lincoln County Process is named after the county in which Jack Daniel’s was originally brewed - over the years, the original Lincoln County was folded into current day Moore County (the Jack Daniel’s distillery is still in Moore County, which is, ironically, dry). A man named Alfred Eaton used charcoal to filter his whiskey in Lincoln County in the 1820s, but some say he learned the process from a South Carolina distiller who moved to Lynchburg around that time. And where that man got the idea is lost to history.

In the modern world, activated charcoal filters are used in everything from cigarettes to cars to homemade coronavirus face masks. But the ubiquitous adoption of charcoal filtration took millennia. The earliest evidence of charcoal being used for purification comes from an Egyptian papyrus dating to 1500 BC. In that instance, the Egyptians applied charcoal to festering wounds to make them less odiferous. Somewhere in the next thousand or so years, people figured out that charcoal was effective on unwanted flavors as well as odors - by around 400 AD, the Phoenicians were using charred barrels to store their water on long sea journeys to improve its taste (creating, essentially, the first ever Brita filter). The system of actually passing a substance through a layer of charcoal to draw out impurities took hold as a large scale industrial practice when the Europeans developed a taste for refined sugar in the 19th century, and they discovered that they could use charcoal to draw unwanted flavor and color components out of beet and cane sugar. But in the intervening years, people all over the world used charcoal as a home method of purification. And it’s likely in that scrappy way that charcoal filtration made its way into the distillation process.

Charcoal Meets Whiskey

Who first applied charcoal filtration to whiskey-making in the United States is a matter of some debate. The Lincoln County Process is named after the county in which Jack Daniel’s was originally brewed - over the years, the original Lincoln County was folded into current day Moore County (the Jack Daniel’s distillery is still in Moore County, which is, ironically, dry). A man named Alfred Eaton used charcoal to filter his whiskey in Lincoln County in the 1820s, but some say he learned the process from a South Carolina distiller who moved to Lynchburg around that time. And where that man got the idea is lost to history.

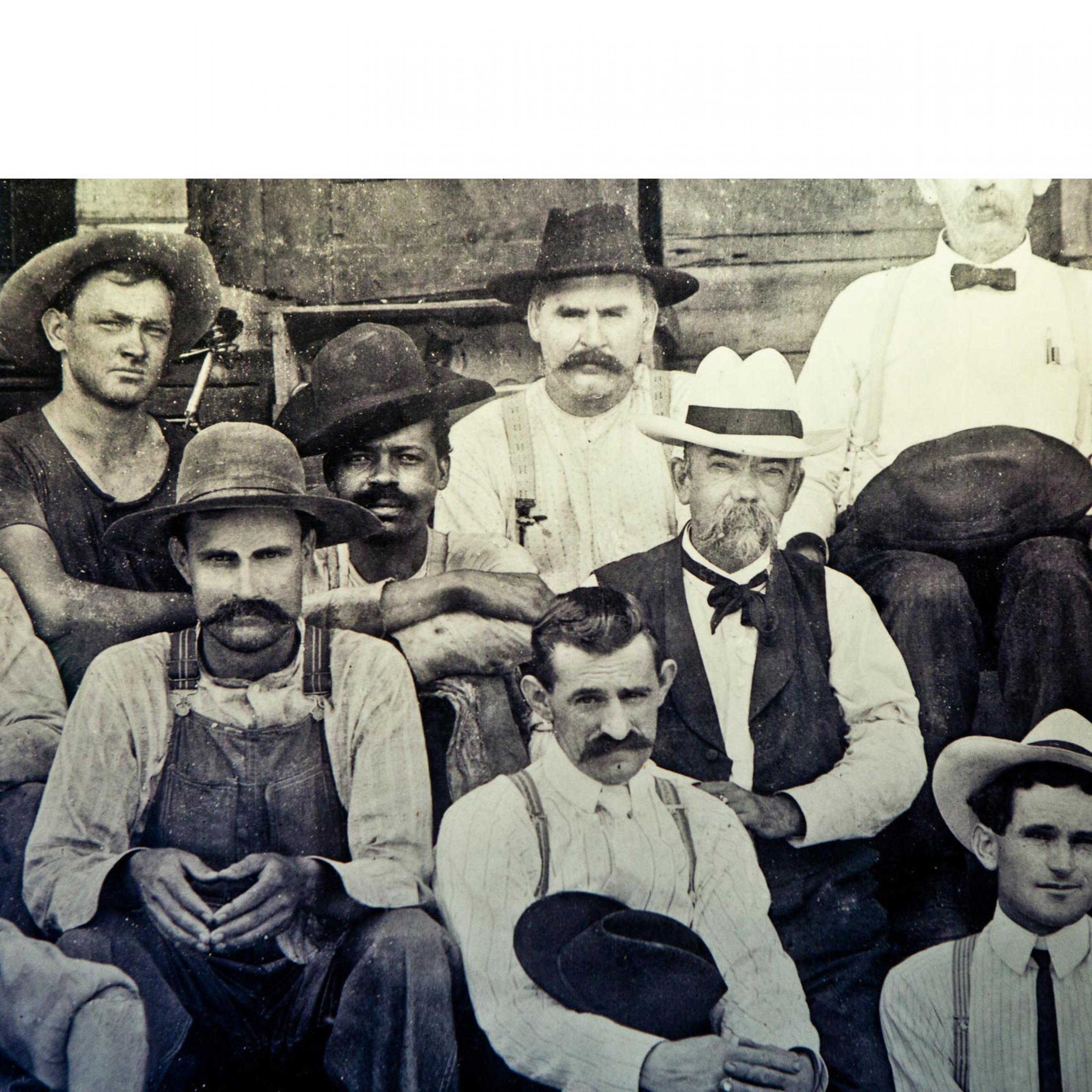

Jack Daniel and one of the sons of Nearest Green who worked for him

Jack Daniel Meets Nearest Green

While some aspects of the history of the Lincoln County process have yet to be unearthed, another part of the story came to light just in the last decade. In 2016, the New York Times published an article about Nathan “Uncle Nearest” Green, the slave who taught Jack Daniel how to make whiskey. Another author, Fawn Weaver, saw the article and spent the next several years researching the full story of Nearest Green. According to Weaver’s research, Nearest Green was most likely a rented slave of the preacher, grocer, and farmer Dan Call. Slaves who knew how to distill whiskey fetched a high price, and so were often rented rather than bought and sold, and Call had Green running his distillery for him. Sometime around 1850, a young boy named Jack Daniel came to work for Call as well. Daniel was the tenth of ten children, and his mother died when he was very young. His first jobs for Call were on the farm, tending animals and doing chores, but Daniel eventually convinced Call to let him work in his distillery. Call told Daniel that Nearest was the best whiskey-maker around, and he taught Daniel everything he knew.

When Call and Daniel went into business together and opened a new distillery, Nearest Green continued to work for them as the first African American Master Distiller on record. Shortly after the end of the Civil War and the Emancipation Proclamation, Call retired from the distilling business and Jack Daniel built his own distillery in Lynchburg. While Nearest Green did not follow Daniel to that new business, three of his sons did. Descendants of Green still work at the Jack Daniel’s distillery in Lynchburg to this day. Since completing her research, Fawn Weaver has also started The Uncle Nearest Foundation and the Uncle Nearest Whiskey brand to commemorate Green’s important contributions to the trade (neither of which are affiliated directly with Jack Daniel's, though the two entities do collaborate on historical projects).

And so it was Nearest Green who taught Jack Daniel about charcoal filtration and built the process into the foundation of the largest American whiskey company. Because it has never been discovered exactly how charcoal filtration was inserted into whiskey-making in Tennessee, Weaver hypothesizes that it may have come from the African practice of filtering water with charcoal to make it more palatable, and been brought to the United States by slaves. As she notes, every aspect of distilling whiskey in the United States can be traced to Scotch and Irish traditions except the charcoal filtration. And when something in the United States drops into our history without a trace, there’s a good bet it came from those whose history and traditions went largely undocumented.

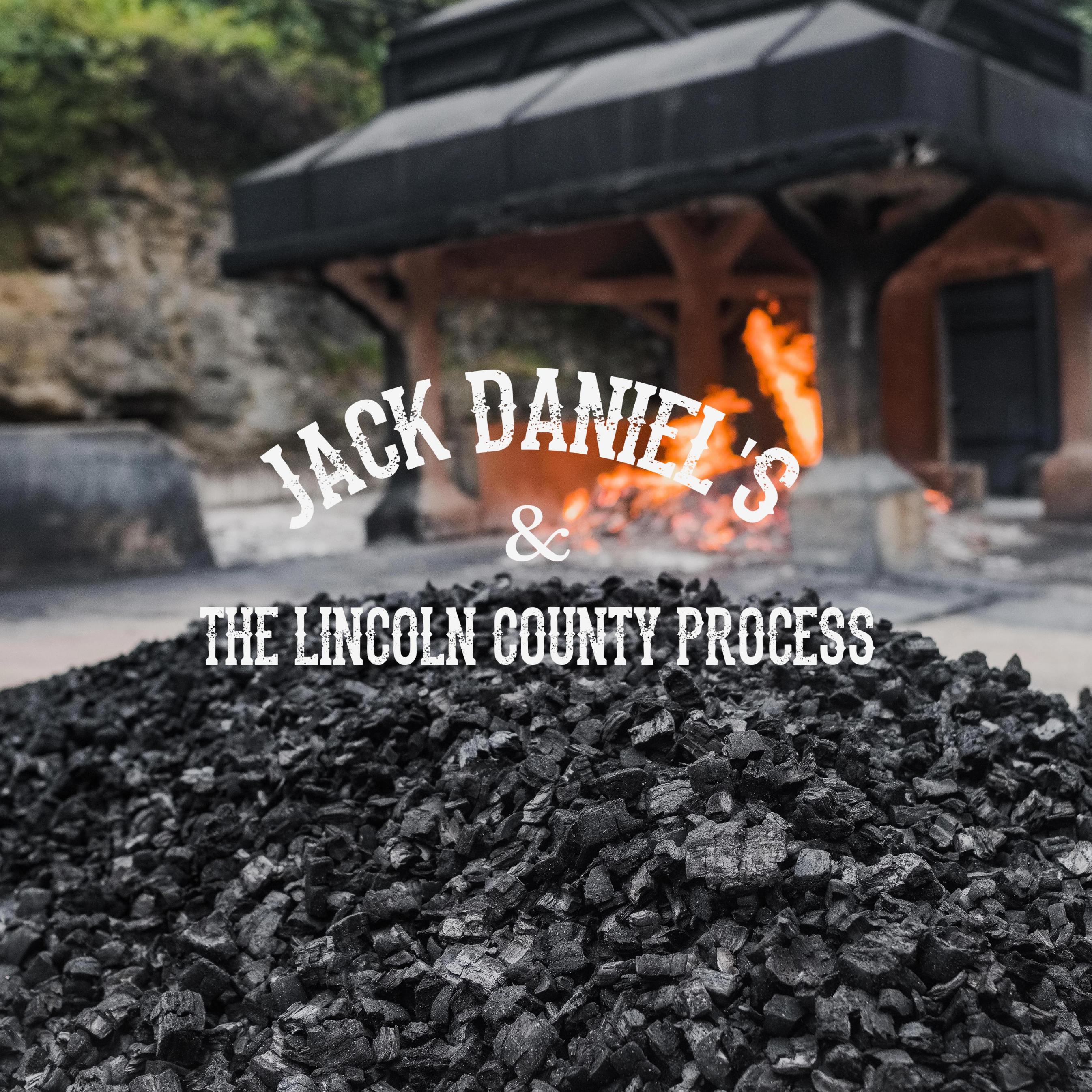

The system developed by Green and Daniel differed from the earlier iterations of charcoal filtration used by Alfred Eaton and others in its extent. While Eaton passed his whiskey through a single inch of sugar maple charcoal, Jack Daniel’s is drip-filtered through a ten foot bed of charcoal made by igniting pyres of sugar maple with new distillate (according to today’s laws whiskey can’t be called “whiskey” until it has been aged).

While some aspects of the history of the Lincoln County process have yet to be unearthed, another part of the story came to light just in the last decade. In 2016, the New York Times published an article about Nathan “Uncle Nearest” Green, the slave who taught Jack Daniel how to make whiskey. Another author, Fawn Weaver, saw the article and spent the next several years researching the full story of Nearest Green. According to Weaver’s research, Nearest Green was most likely a rented slave of the preacher, grocer, and farmer Dan Call. Slaves who knew how to distill whiskey fetched a high price, and so were often rented rather than bought and sold, and Call had Green running his distillery for him. Sometime around 1850, a young boy named Jack Daniel came to work for Call as well. Daniel was the tenth of ten children, and his mother died when he was very young. His first jobs for Call were on the farm, tending animals and doing chores, but Daniel eventually convinced Call to let him work in his distillery. Call told Daniel that Nearest was the best whiskey-maker around, and he taught Daniel everything he knew.

When Call and Daniel went into business together and opened a new distillery, Nearest Green continued to work for them as the first African American Master Distiller on record. Shortly after the end of the Civil War and the Emancipation Proclamation, Call retired from the distilling business and Jack Daniel built his own distillery in Lynchburg. While Nearest Green did not follow Daniel to that new business, three of his sons did. Descendants of Green still work at the Jack Daniel’s distillery in Lynchburg to this day. Since completing her research, Fawn Weaver has also started The Uncle Nearest Foundation and the Uncle Nearest Whiskey brand to commemorate Green’s important contributions to the trade (neither of which are affiliated directly with Jack Daniel's, though the two entities do collaborate on historical projects).

And so it was Nearest Green who taught Jack Daniel about charcoal filtration and built the process into the foundation of the largest American whiskey company. Because it has never been discovered exactly how charcoal filtration was inserted into whiskey-making in Tennessee, Weaver hypothesizes that it may have come from the African practice of filtering water with charcoal to make it more palatable, and been brought to the United States by slaves. As she notes, every aspect of distilling whiskey in the United States can be traced to Scotch and Irish traditions except the charcoal filtration. And when something in the United States drops into our history without a trace, there’s a good bet it came from those whose history and traditions went largely undocumented.

The system developed by Green and Daniel differed from the earlier iterations of charcoal filtration used by Alfred Eaton and others in its extent. While Eaton passed his whiskey through a single inch of sugar maple charcoal, Jack Daniel’s is drip-filtered through a ten foot bed of charcoal made by igniting pyres of sugar maple with new distillate (according to today’s laws whiskey can’t be called “whiskey” until it has been aged).

The Science

When Nearest Green and Jack Daniel first started filtering their whiskey, it wasn’t common to age the product of stills before selling it, and without aging, distillate was a harsh substance. Filtering it was a way to mellow the substance and make it more palatable right away. Charcoal filtering works by “adsorption”: the charcoal molecules bind to those of undesirable flavor compounds. What is leached from the whiskey is called “fusel oil” and is comprised of several harsh, unpleasant tasting alcohols, largely amyl alcohol.

When Nearest Green and Jack Daniel first started filtering their whiskey, it wasn’t common to age the product of stills before selling it, and without aging, distillate was a harsh substance. Filtering it was a way to mellow the substance and make it more palatable right away. Charcoal filtering works by “adsorption”: the charcoal molecules bind to those of undesirable flavor compounds. What is leached from the whiskey is called “fusel oil” and is comprised of several harsh, unpleasant tasting alcohols, largely amyl alcohol.

Making charcoal at the Jack Daniel's Distillery in the early 20th century

The fusel oil has an oily texture that can also cloud whiskey when it’s chilled. But filtering is a matter of taste - some believe it robs a spirit of desirable character. And several Tennessee whiskey makers have gotten exemptions from the Lincoln County Process requirement, including, ironically, Benjamin Prichard’s - the only remaining distillery in the current-day Lincoln County. But for Jack Daniel’s enthusiasts, the Lincoln County Process and charcoal filtration are inseparable from the legacy of fine whiskey in the United States.

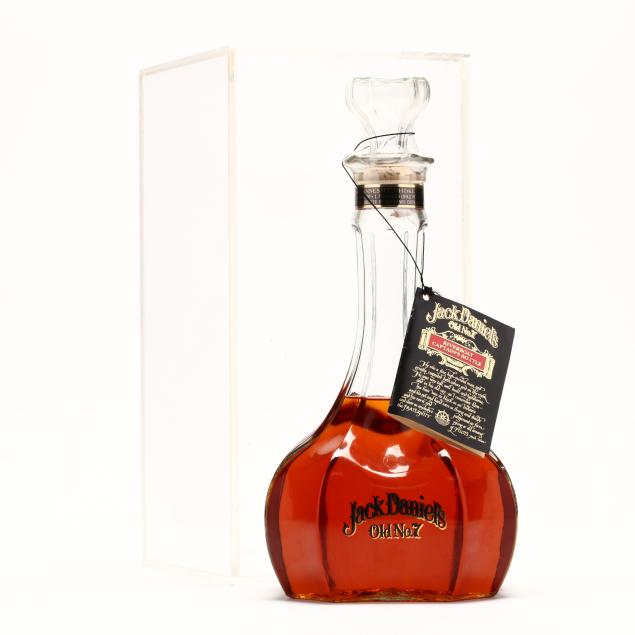

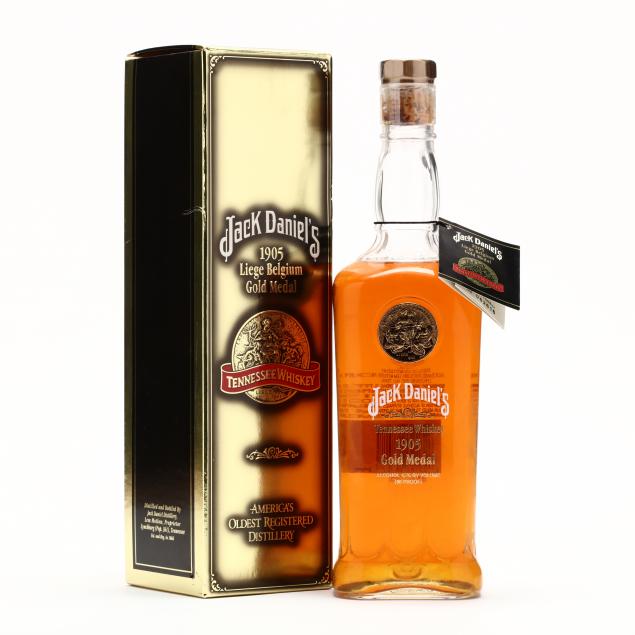

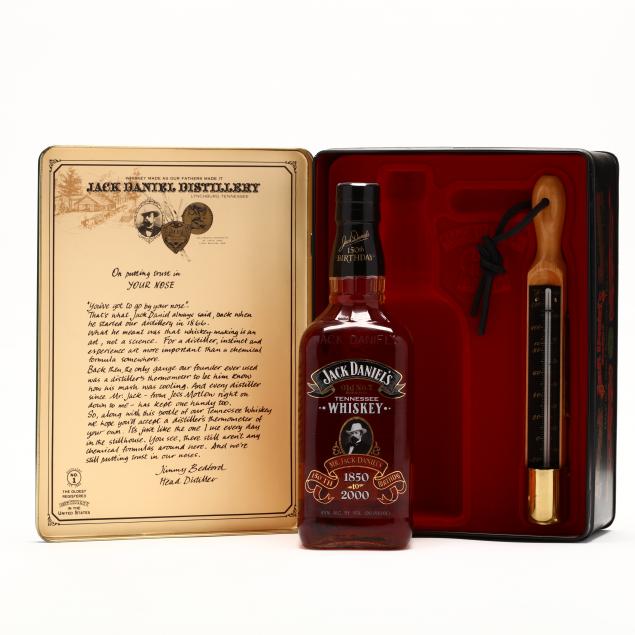

Highlights from the selection of Jack Daniel’s in our Fine Wine & Spirits Auction are below. View the full catalogue for the sale here.

Fine Wine & Rare Spirits

Thursday, June 11th

1:00pm (EDT)

Highlights from the selection of Jack Daniel’s in our Fine Wine & Spirits Auction are below. View the full catalogue for the sale here.

Fine Wine & Rare Spirits

Thursday, June 11th

1:00pm (EDT)